Tony Robbin

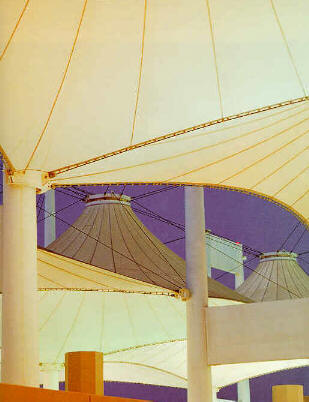

The Hajj Terminal at the King Abdulaziz International Airport. Skidmore, Owings, and Merrill, architect and engineer; Horst Berger, consulting engineer; Birdair, membrane installer. (Photo: Jay Langlois, Image Source, Toledo, Ohio) |

Engineering a New Architecture

From the book by Tony Robbin

Yale University Press

1996

How new engineering materials and techniques are influencing

architectural design.

Membranes

Tensegrity

Deployable Structures

Shells

Hybrids

Structural Morphology

Materials

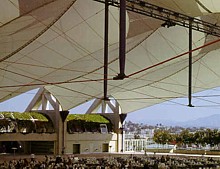

The San Diego Convention Center. Arthur Erikson Architects, architect; Horst Berger Partners, roof engineer; Birdair, membrane fabricator and installer. (Photo: Tony Robbin) |

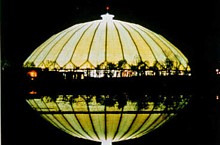

The M & G Research Laboratory in Venafro, Italy. Samyn and Partners, architect and engineers. (Photo: Matteo Piazza) |

Membranes

Since the 1960's, Frei Otto, Horst Berger, and David Geiger championed the idea of using fabrics for architectural structures. Their unassailable argument was that only fabric membranes are truly lightweight, so only membranes are suited to spanning large areas. Membranes - inflated by air pumps, stretched over tent poles, or hung from exterior scaffolding- are desirable for their quick construction and disassembly, their translucence, and their startling appearance.

Membranes are now strong, permanent, fireproof, and insulated. In the United States there are more than 250 large, permanent membrane structures, in cold climates as well as warm ones, delivered on schedule and on budget to their occupants, signed off by fire and building inspectors, and insured by companies not known to be cavalier with money. In short, they are buildings.

The Amagi Dome in Suzenzji, Japan. Masao Saitoh, architect and engineer. (Photo: Masao Saitoh) |

Gymnastic Hall, Korean Olympics. David Geiger, engineer. DCI membrane manufacturer and installer. (Photo: Geiger Engineers) |

Tensegrity

When French engineer Rene Motro built a lightweight, membrane structure in the South of France, trucks brought massive amounts of concrete to the site. How could the structure be called lightweight? his client wanted to know. The innocent question became a koan that led Motro to study tensegrity structures. Tension structures must be attached somewhere; otherwise the tension disappears and the membrane flies away. These structures are usually attached to the ground; the earth is the weight which keeps the membrane tight. But making the connection between earth and membrane is not easy and often massive concrete anchors below ground are needed. Tensegrity systems are self anchored; they pull only against themselves. Such structures are self-stressed in a "closed" system.

David Geiger's cable dome system. (Drawing: Geiger Engineers)

The Palau Sant Jordi in Barcelona, Spain. Arata Isozaki architect; Mamoru Kawaguchi, engineer. (Photo: courtesy Mamoru Kawaguchi) |

The Dome in Izumo, Japan. Masao Saitoh, architect and engineer. (Photo:courtesy Masao Saitoh)  |

Deployable Structures

An old problem for designers is how to avoid building structures twice: once in the form of a wasteful, dangerous, temporary scaffolding, and again in the final material. Now new technology fully solves the old problem of how to build a roof when there is not already one to stand on.

World Memoral Hall in Kobe, Japan. Mitsumne, architect; Mamoru Kawaguchi, engineer. (Photo: Mamoru Kawaguchi)

A distinction must be made between prefabrication and deployment, as all architecture is prefabricated to some degree; ore for steel girders is not mined, smelted, or forged at a Manhattan building site. Deployment concerns not the premanufacture of elements but the more or less complete pre-assembly of an entire structure in a factory, the collapsing of the structure for shipping, and the unfurling or deploying of the structure on site.

The BP gas station on the Bern-Zurich Highway. Heinz Isler, engineer and fabricator. (Photo: courtesy Heinz Isler) |

Shells

Classical domes have a thickness-to-radius ratio of 1:50; egg shells have a t/r of 1:100; modern concrete shell domes can be built to the astounding ratio of 1:800. Constructed with small quantities of simple, inexpensive, low-tech concrete and wire mesh, these structures are safe as well as beautiful. Practitioners have come to the counter-intuitive realization that the strength of shells results from their shape, not their mass: they embody -in concrete - the famous architectural dictum "less is more."

Gymnasium in Sakata, Japan. Masao Saitoh, architect and engineer. (Photo: courtesy Masao Saitoh) |

Hybrids

Separate structural systems are well understood:

not so well studied is how they can be combined in hybrids. As with plants, good hybrids are not genetic monsters, but sly superimpositions of capabilities. Hybrid buildings subtly alternate between two intertwined structural systems, one for normal loads and another that can respond to new circumstances with latent strengths.

In the Sakata Gym, built in the high snow region of the Yamagata Prefecture in 1991-92, Masao Saitoh and architects Taniguchi and Associates, solved a complex and difficult loading problem. During the winter, snow loads can be double the self-weight of the roof, yet the site of the gym, a park with an existing small art gallery located in the midst of rice fields, required a flat roof. To build a flat or slightly curved roof that spanned the required 53 meters, a conventional truss would have to be massive, very deep, visually oppressive, and out of character with the delicate park buildings and setting. The solution was to design two structures for the two different loading conditions and allow the building to convert from one to the other, to inhale and exhale with the rhythm of the seasons.

The COAST quasicrystal at Denmark's Technical University. Tony Robbin, artist; Erik Reitzel, engineer; RCB Precision of Mount Vernon, New York, fabricator. (Photo: Poul Ib Henriksen) |

|

Structural Morphology

A few dozen engineers and architects share the view, currently considered revolutionary, that geometry drives architecture forward.

To be ignorant of complex polyhedra, four-dimensional geometry, fractals, 3-manifold topology and the like, to have the cube and the octatruss as the only geometric options is to restrict structures with a severity that not even nature demands, its severe doctrine of optimization notwithstanding.

Moreover, there are aesthetic considerations; technobuffs may look lovingly at row after row of tetrahedra, but the public sees these as mechanical and boring, just more inhuman examples of Eiffel-tower truss work. Why bother looking at something we just saw!

But the complaint against mechanistic architecture, when considered honestly, is not that geometry is alien to human structures -geometry is unavoidable in structures; the complaint is that the geometry used is at least 100 years old, and was fresh in another context entirely. The computer makes this new impetus to mathematically generated form possible.

Materials

Today's engineers, who already have Kevlar cords stronger than steel, will soon use concrete springs to absorb crashes, erect glass walls stronger than solid aluminum, work with nickel-titanium sheets that can fold up and unfold by themselves on command, and use rigid protective coverings that can heal themselves when fractured. Science-fiction materials are becoming reality, and just in time: forests are dwindling, and the true costs (cleaning up the environmental damage) of coal, crude steel, and gypsum price traditional materials higher and higher. The new model of efficient structures will incorporate materials that erect, mechanically service, maintain, and repair themselves.

Conclusion

In a televised interview, Frank Lloyd Wright defined modern architecture: it was not architecture made in the modern period but rather "organic" architecture made with tensile strength. He called the new principle "tenuity" and illustrated it by lacing his fingers together to make a tenuous, flexible but strong connection, which he associated with a railway trestle bridge. Post and beam construction, in contrast, is stacked, fist over fist, with neither tensile strength nor unity.

In the interview, Wright said that tenuity - based on the long-span capabilities of steel and glass - compelled him to develop "open plan" architecture, a design concept he said was his greatest artistic contribution. Wright, the master designer, thus gave priority to engineering. An engineer as well as an architect (he left engineering school just three months short of his degree)

Wright saw no essential conflict between engineering and design; rather he saw that the converse was true: new aesthetics are the inescapable consequence of new engineering techniques. Wright claimed that if the ancient Greeks had steel and glass, they would have made modern architecture back then, engineering birthing aesthetics. He expressed loathing for those who clung to an architectural style when there was no functional or structural reason to do so.

The engineering of the present is ripe with possibilities for innovative design. Membrane structures redefine the meaning of inside and outside. Tensegrity systems of cables and rods elegantly balance the tension and compression in materials that hold up buildings. The rationality and efficiency of deployable structures, made at one location or at ground level on site and then erected in one operation, add a new dimension to the aesthetic appreciation of architecture. Shells, hybrids, computer-driven morphology studies, and exotic new material also enrich architects' choices.